Uncommon Engineers.

Reliable Performance.

ABOUT

Capabilities

A key advantage for Tulsa Combustion is having in-house capabilities in design, engineering, project management and manufacturing. This promotes consistency of our processes and reliable performance of our work products.

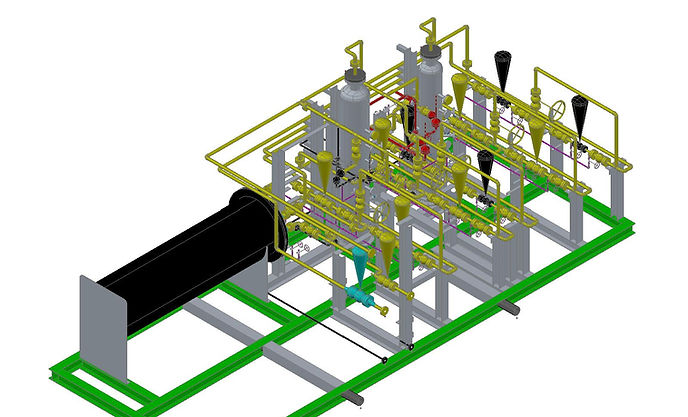

Our in-house manufacturing capabilities address pressure vessels, piping, skidded modules, refractory components and process controls. Talented fabrication specialists, ample floor space over 100,000 square feet, ASME qualification, AWS welding procedures, non-destructive testing protocols and quality control systems provide the infrastructure to deliver superior equipment at competitive prices.

To the old proverb “If you only have a hammer, everything looks like a nail” -- Tulsa Combustion has a full set of tools

Experience

Our industry has made most of its important advances not through fundamental R&D but rather by collaboration between combustion specialists and the operating staff of their customers, working to achieve practical results with real-world process improvements. That is the primary experience of Tulsa Combustion’s senior staff. It is the way we work with our customers today.

Some of the largest combustion systems in the world used by globally integrated energy companies have been realized by members of our staff. Tulsa Combustion is attuned to smaller operations that face challenges which are often technically unique and require creative, cost-effective responses.

The experience of Tulsa Combustion’s staff is enhanced by extensive involvement in field start-up of equipment and systems. Furthermore, some team members have worked in operations for energy companies, gaining an appreciation of the values important to our customers.

Another important dimension of the careers of our staff is working with energy companies around the world. This has provided an understanding of local business cultures and the need for technologies appropriate to local work environments.

Expertise

Individually, our staff members are among the industry’s pioneers – developing technologies and standards in collaboration with operating companies over decades. Indeed, they hold over 50 patents related to important applications in our arena. Collectively, they have built a Company with a track record of reliable performance in meeting customers’ objectives.

Serving in key technology and management roles in the earliest firms in our industry, our senior staff participated in the evolution of best practices and standards developed over years of systematic innovation, including the vital areas of safety and environmental compliance.

Core disciplines are maintained in-house: design engineering, project management and the essential crafts needed in manufacturing. Specialized knowledge is brought to bear through a network of industry experts with personal connections to our staff.

A cornerstone of Tulsa Combustion is cross-disciplinary integration and a broad knowledge of inter-related unit operations, so that internal consistency and conformity are achieved in both design and project execution.